Cloud deployment, 3D synthetic data

Design for X & mass production readiness

Project abstract

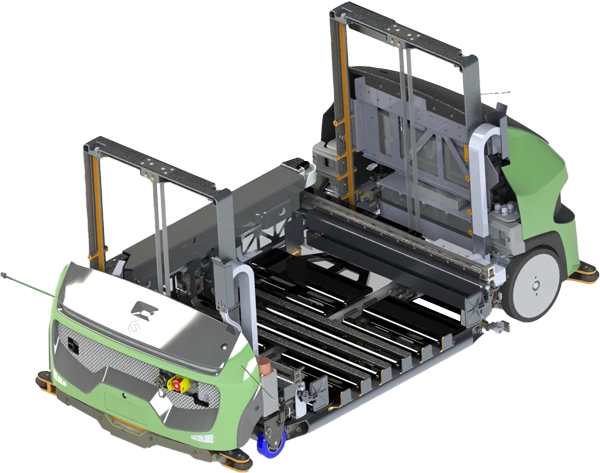

A market leader in warehouse automation required a small robot to transfer individual packages from a human-controlled picking station to a container.

In response, Kickmaker designed a custom robot and integrated it into the customer’s existing fleet management and routing system.

Technical developments

- The first fully featured MVP was completed in three months, including specification and solution benchmarking phases.

- A fully integrated prototype for field testing and scaling was finished in under nine months.

- Achieved a BOM cost of less than $4,500 at a minimum order quantity of 1,000.

- Developed and set up a manufacturing test site at a Kickmaker Assembly Line (KAL) in one of Kickmaker’s facilities.

Key achievements

- Utilized a DFX-centric development approach.

- Assembled a multi-skilled team that included hardware, application and embedded software, procurement, and certification experts.

- Implemented a three-stage project plan over nine months, covering specification, solution benchmarking, rapid prototyping, and testing of a ready-to-use prototype for qualification.

- Guaranteed compatibility with a network of warehouse and AGV robots.

Quality Work

“The project was really interesting as we were working on the robustification of a solution used in production.Our focus was on the development of the framework and tools.”

Baptiste Petit, Software Developer and Lead Tech at Kickmaker