Technical speciality: Industrialization, Mechanical Engineering, and Electronic Engineering

Pazzi Robotics : Industrialization audit for the automated pizza-production store

Project abstract

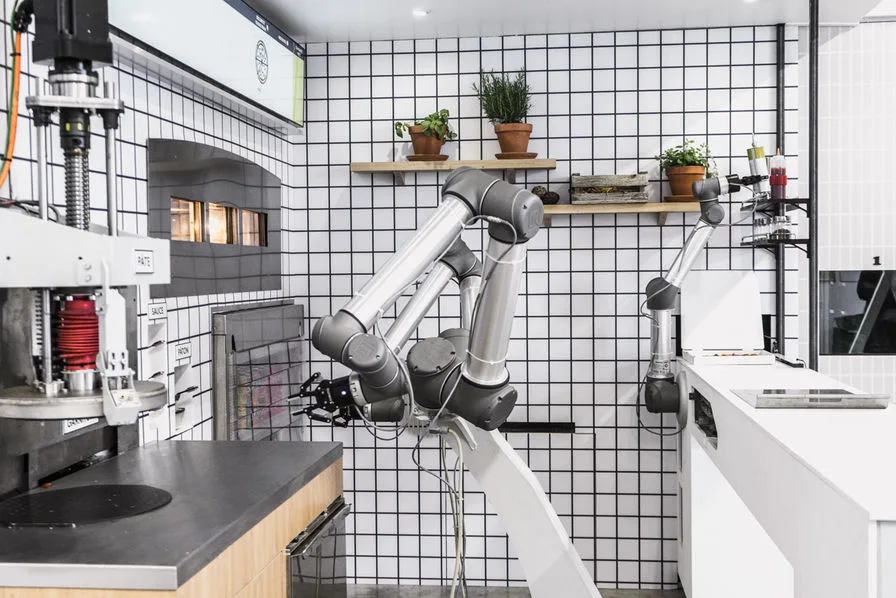

Pazzi Robotics transformed the fast-food industry with their pizza robot by creating the first fully autonomous restaurant. Kickmaker developed a scalable prototype of a cloud-connected, machine-learning platform featuring robots and robotic modules, allowing the restaurant to operate independently.

Pazzi’s store required only a few dozen minutes of maintenance each day, mainly for cleaning.

Technical developments

- Conducted a comprehensive audit of the entire system to identify areas for maximum industrial and cost efficiency

- Aligned the industrialization roadmap with store opening milestones

- Redesigned the prototype using DFx principles

- Achieved BOM cost reductions

Key achievements

Kickmaker was brought in to enhance safety and reliability through state-of-the-art automation systems (>300 units).

- Reduced costs from $1.2M to $430K but explain this statement in detail

- Decreased maintenance time from hours to minutes

- Ensured compliance with health and safety standards (including complex management of flour, spills, etc.)

- Developed cleaning procedures but explain this in detail

- Enabled the company to secure an $11M funding round

- Halved the cost of the robot

Quality Work

“Working on Pazzi was incredibly rewarding. It allowed us to thoroughly explore the entire system, including the technical teams and industrial partners, leading to a comprehensive industrialization plan that helped them secure funding.”

Bruno Venancio, Project Manager Kickmaker